Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Train/Truck Loading Station(TLO)

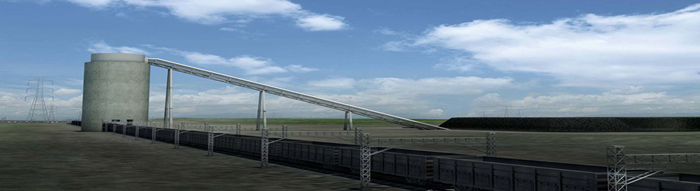

Simulation of the operating process of an automatic train loading station

1. Introduction of Train/Truck Loading Station(TLO)

Train/Truck Loading Station(TLO) is an important bridge to connect the raw bulk material and steel industry and energy suppliers. The bulk material is discharged from weighing hoppers and top loaded into wagons ready to carry the goods to the customers. Allowing for a fully automatic operation of this loading station, the following key functions have to be defined:

1) control of the shunting robot

2) positioning of the wagons below the loading facility

3) filling of the weighing hoppers

4) control of material discharge.

2. Full-automatically Controlled Train/Truck Loading Station(TLO)

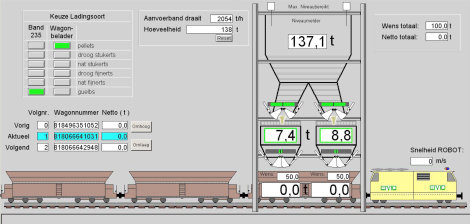

In fully automated mode, the radio remote controlled shunting robot pulls the train across the loading facility at appropriate speed. Simultaneously, four 2-d laser scanners track the wagon movements, detect the position of the hatchways, check the wagons for remaining quantities, and monitor loading as well as filling degree.

A large amount of data is available for many types of wagons and bulk materials, ready to be retrieved by the system, to allow for fully automated mode from the railway control center transfer point up to the end of loading.

Process visualization in the control pulpit

3. Features of Train/Truck Loading Station(TLO)

1) Electronic control system uses digital field bus, control system uses field data bus protocol.

2) Hydraulic system uses digital servo hydraulic systems, including servo hydraulic cylinders, servo-hydraulic proportional valve, the flow piston pump and so on.

3) Weighing sensor adopts the form of shear beam to avoid the weighing inaccuracy caused by material impact during the weighing process , improve weighing accuracy and shorten the reading time,therefore, improve the loading speed.

4) Buffer warehouse, quantitation warehouse and overall appearance adopt cylinder - conical design.

5) Equipped with plastic alloy slider, the support part of the gate has the following advantages: low coefficient of friction, self-lubricating and lasts for longtime.

6) Thermal insulation, the outer wall of the loading chute, exposed parts of the hydraulic tubing wrapped around self-regulating heating cables to ensure that the equipment works properly.

Oriented loading to take full advantage of wagon capacity

It may be reasonable to perform charging in terms of mass or volume depending on the specific weight of the material. Thus, it is possible to make best use of the available loading capacity with regard to the allowable load per axle. Specifically heavy bulk material, such as ore, is generally charged approaching the load limit but 1 t. With lighter goods, e.g., coal and coke, corresponding loading profiles allow for an optimum volume usage. In practical operation, figures of between 95 and 98 % are obtained without overloading the wagons.

The existing Train/Truck Loading Station(TLO) are able to be improved through upgrades from automation to track scales and general process improvements. We can undertake a Fitness Check and recommend solutions to make your Train/Truck Loading Station(TLO)

More efficient, improve loading times and throughput, improve loading target in each wagon, reduce operating costs or improve the safety of the system.

Contact us:

|

|

Serena Fu |

Kira Zhang |

Teresa Zheng |

|

|

serena.fu@hot-mining.com |

kira.zhang@hot-mining.com |

teresa.zheng@hot-mining.com |

|

Skype |

Serena20140924 |

kira.zhangjing |

teresa.zheng123 |