Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Comparison Analysis of XRT Intelligent Sorter and DSM Bath in Coal Washing

1 Comparison of Basic Principle

1.1 Working Principle of XRT Sorter

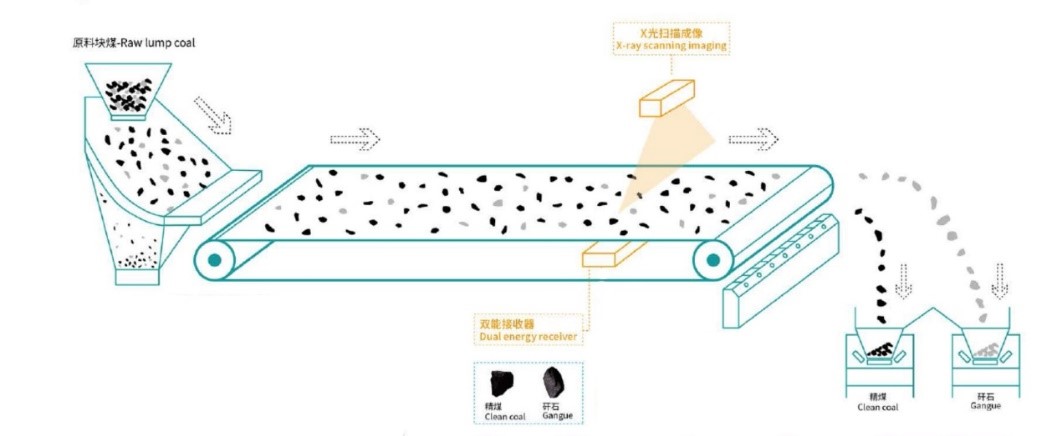

XRT Intelligent sorter is an automatic sorting equipment based on the advanced Imaging technology and AI technology. The coal and gangue are automatically analyzed and identified by X-ray imaging system, which can obtain the material characteristics, and control the high-pressure wind to blow the target materials away.Figure 1. The Working System of X-ray Sorter

1.2. Working Principle of DSM Bath

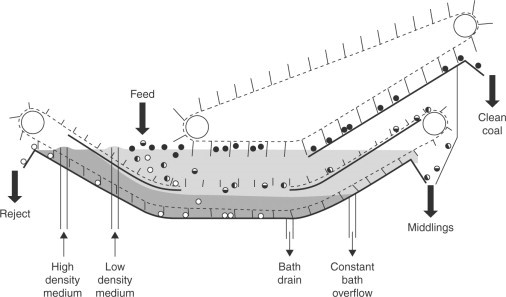

The DSM Bath sorts coal in the gravity field based on the principle of Archimedes' law. The material that is below the medium’s density will float above and pass the overflow as clean coal product under the action of horizontal flow; the material that is higher than the density of medium is gangue, which will sink to the bottom of the bath, and will be scraped out by the chain scraper with low operating speed. In order to effectively sort the materials, the dense medium suspension in the machine must be kept stable and evenly distributed.Figure 2. The Working System DSM Bath

1.3 Comparison Analysis

From the perspective of sorting principle and equipment structure, the DSM Bath machine is relatively complicated, and its’ sorting accuracy is easily affected by factors such as suspension density, rising water flow, and gangue plate height. And the sorting accuracy is limited. While the XRT intelligent sorter relies on a high-precision algorithm to intelligently identify each particle, that is, each piece of coal is independent and can be recognized quickly and accurately to exclude the gangue with different particle sizes.2. Comparison of technical Parameters

2.1 XRT Intelligent Separator

※Wide processing size range: It can handle averagely 10- 300mm raw coal. The upper limit of separation is 300 mm and the lower limit is 10 mm.※High separation accuracy: The rate of gangue removing is over 95%, the rate of gangue in coal is less than 2%.

※Great processing capacity: The processing capacity is 300t/h for the materials with different particle sizes.

※High-level intelligence: Workers are not required to be on duty for a long time, and the equipment fault can be self-detected.

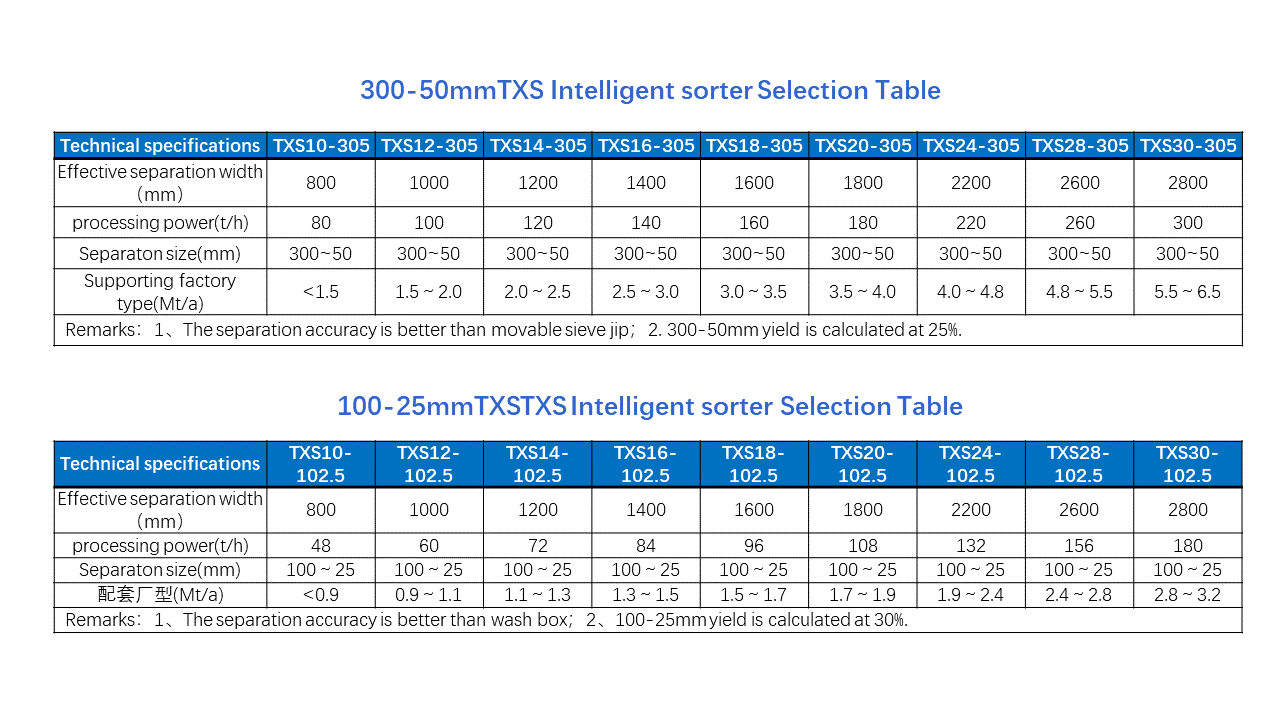

Below is the technical table of TXS Intelligent Sorter of HOT Mining Tech.

Figure 3.

2.2 Dense Medium Bath

※Wide processing size range: It can handle averagely 6- 300mm raw coal.※Strong adaptability to coal quality fluctuation, low operation cost and wide range of gangue discharge.

Figure 4 Main Technical Parameters of a DSM bath

|

Capacity |

Feeding Size |

Power |

DSM cycle |

Max Gangue Discharge |

|

(t·h-1) |

(mm) |

(kw) |

(m3·h-1) |

(t·h-1) |

|

160~220 |

300~13(6) |

15 |

500~600 |

80 |

2.3 Machine Advantages

2.3.1 Simple Structure and ProcessDifferent from the traditional coal preparation process, XRT intelligent sorter does not need water in the screening process, that is to say, compared with DSM Bath, it not only has no slime water pressure filtration system and dense medium recovery system, but also does not need pipeline connection equipment.

2.3.2 Higher Sorting Accuracy

XRT intelligent Sorter can accurately identify coal and gangue by building model and data analysis, and realize the separation of coal and gangue with different particle size or the same particle size, which is far higher effective than the traditional coal preparation process.

2.3.3 Lower Cost

Different from the traditional coal preparation process, XRT intelligent ore sorter mainly uses x-ray to identify coal and gangue, and the execution medium is high-pressure air processed by air compressor. Therefore, air compressor is the main energy consumption device. While the traditional process requires a large amount of water and dense media, accessary equipment, complex system, high energy consumption, high cost of under construction.

2.3.4 Less Mammal

Although the DSM bath has also been automated, the large particle size still needs manual selection, which requires greater labor intensity and is prone to accidents; XRT sorter has a higher degree of automation with advanced AI algorithm and in the production process, the accident rate will be greatly reduced by remote control.

2.3.5 Environment Pollution Issue

Traditional coal washing will produce slime in the process which is often discharged as waste when the product coal cannot be mixed with product coal and cannot be sold separately, due to the low calorific value of the slime. It makes a great pollution to the environment. The XRT intelligent sorter doesn’t produce secondary slime because there’s no water, and the calorific value of sorted coal is high without any cake, which can be directly incorporated into the product coal for sale. It effectively solves the difficult problem of sticky wet slime treatment and avoids environmental pollution.

3 Conclusion

Compared with the traditional DSM bath, XRT intelligent sorter has advantages of highly automated, water saving, low operation cost, high separation accuracy, which greatly improving the utilization rate of coal and greatly increasing economic benefits. The application of XRT intelligent sorter adapts to the development trend of future coal industry.

More details about HOT XRT Intelligent Sorter, pls contact:

Email: kira.zhang@hot-mining.com

Tel/WA: +86 15281051932

Email: teresa.zheng@hot-mining.com

Tel/WA: +86 15281626323

Web:http://www.hotminingepc.com/xrt-sorting-coal-mineral-ore