Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Discussion on the Configuration Forms of Knelson Concentrators

in Gravity Separation Process

1. Preface

In recent years, due to the rapid rise of gold price, the economic benefits of gold mining and production companies have been significantly improved, and a large number of advanced world-renowned mineral processing equipment have been applied in China, due to their advantages of high equipment efficiency, low failure rate and easy operation, as well as simple process configuration and so on, they are generally recognized by mine and industry experts, these equipment include: crushing and screening equipment produced by Metro and Sandvik, Knelson Concentrator, etc. They have brought revolutionary development to China's mineral processing production, and the scale and technical indicators of mineral processing have also been greatly improved.

ShanDong YinGeZhuang Gold Mine was the first to import the Knelson Concentrator into China for recovery the coarse gold. Later, HeNan JinQu Gold Mine and Shanxi YiXingZhai Gold Mine also successively applied it in coarse gold recovery. Since then, the Knelson Concentrator has been rapidly promoted and applied in other mines in China, and configuration forms of Knelson Concentrators in gravity separation process has also been developed.

The Knelson Concentrator can be configured before classification or after classification. Because the spiral classifier is often used in the classification of gold mineral processing plants in China, the former configuration is more used in China. However, hydrocyclones are often used for classification abroad, therefore, Knelson Concentrator is usually used to separate coarse gold from underflow by hydrocyclones. Knelson Concentrator uses a large amount of water, resulting in a large water content of tailing after separation, so it must be concentrated before returning to the ball mill for regrinding.

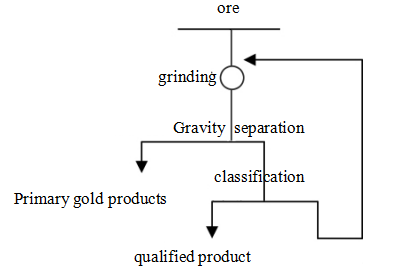

Figure 1 Chinese process configuration

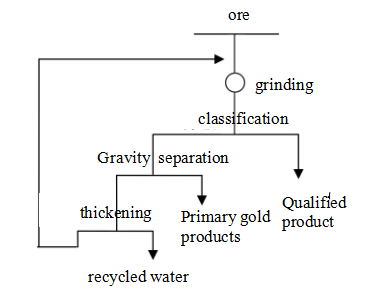

Figure 2 process configuration in other countries

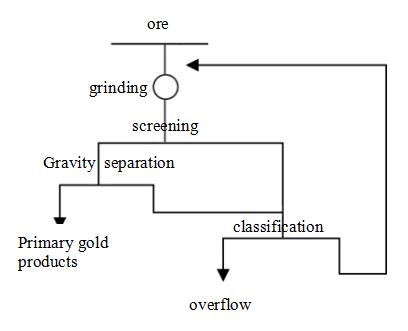

Since the feed size of Knelson Concentrator must be less than 6 mm, it is necessary to separate the material larger than 6 mm with a sieve and return it directly to the classification equipment or ball mill. This paper will discuss the advantages and disadvantages of several configuration forms of Knelson Concentrator in China for reference.

2. Configuration of Fixed Sieve, Knelson Concentrator and Spiral Classifier

In this way, the discharged of ball mill is divided into undersize material and oversize material through a fixed sieve installed at the discharging port of ball mill. The oversize material goes directly into the spiral classifier for classification. The undersize material is fed into the Knelson Concentrator for gravity separation and recovery of coarse gold. The tailing of Knelson Concentrator are pumped to the classifier for classification. The configuration form is shown in Figure 3.

Figure 3 Process Configuration of Fixed Sieve, Knelson Concentrator and Spiral Classifier

The advantage of this kind of configuration form is to make full use of the height difference between the ball mill and the classifier, and directly feed the large-grain ore into the classifier, which reduces the wear of the pump caused by the large-grain ore. The disadvantage is that the screening effect of minerals is unstable due to the frequent blockage of the screen hole, the amount of undersize minerals is unstable, the screening efficiency is low, and the recovery index of Knelson Concentrator is not as good as expected. (This configuration form is used in JinQu Gold Mine in HeNan Province)

3.Configuration of Linear Vibrating Sieve, Knelson Concentrator and Spiral Classifier

This configuration can realize the recovery of coarse gold from the ore by Knelson Concentrator directly, and maximize the recovery rate of gravity separation. Gravity tailing is pumped to spiral classifier for classification. However, due to the height difference between ball mill and spiral classifier, a lot of mineral processing plants can not directly install linear vibrating screen, and result that this configuration form is not easy to achieve and has few practical application.

4. Configuration of Linear Vibrating Screen, Knelson Concentrator and Hydrocyclone

This configuration can make full use of the height difference between different equipment to realize the slurry self-flow. In this way, the use of pumps can be reduced, the process operation is simpler, the automation control can be easily realized, the sanitary conditions can be better, the recovery of coarse gold is more thorough, and the recovery rate of gravity separation is higher. When using this configuration form, it is better to use overflow ball mill grinding and install reverse winch screen at the discharging end of ball mill to avoid discharging large ore and crushed steel balls, and reduce the wear of pump, as well as ensure the better classification efficiency of hydrocyclone (This configuration form is used in YiXingZhai Gold Mine of Shanxi Province).

5. Configuration of jig, Knelson Concentrator and Spiral Classifier

This configuration is to feed the concentrate of jig into Knelson Concentrator and enrich the super-concentrate. The tailing of jig is pumped to spiral classifier for classification. That is to say, the jig is used not only as separation equipment, but also for classification. When this configuration is applied in practice, the yield of the jig is enlarged and the function of the jig as a sieve is brought into play. In this way, the influence of large particles on gravity separation is solved, and the recovery rate of simple jig gravity separation is improved.

But its disadvantage is that the limitation of recovering fine coarse gold by jig prevents some of the fine coarse gold from entering Knelson Concentrator for separation, which affects the recovery rate of gravity separation. The use of jigs increases water consumption. Sometimes concentration/dewatering must be used in order to ensure the requirements of operating conditions in the next process and make the process complicated and the operation difficult to control.

With the application of Knelson Concentrator, it has developed from one stage to two stages Knelson gravity separation, and has been applied to the regrinding and classification process of gold concentrate in leaching operation to recover the coarse gold, avoid the deposition loss of coarse gold in the leaching process and improve the recovery rate of gold.

6. Conclusion

1) Knelson Concentrator is an excellent and efficient gravity separation equipment. Each configuration form has its advantages and disadvantages, and the appropriate process should be determined according to actual production and site conditions.

2) The choice of different form is determined by the ore properties of the selected minerals. In actual production, the appropriate number of gravity separation operations should be selected according to the size distribution characteristics of the target minerals, so as to improve the recovery index of gravity separation as far as possible, and realize the principle of early recovery and more recovery.

3) The selection of the Knelson gravity separation process should be based on the selection index and the requirements of the next process, to minimize the use of the pump, to facilitate operation, to facilitate automatic control, and to maximize economic benefits.