Company:Chengdu Cobalt Mining Co., Ltd

Email: sales@hot-mining.com

Phone:+86 28 83311885

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

How could coal washing plant_CHPP be better?

A flexible flow sheet would bring better operation performance, it doesn’t matter that R.O.M coal is good or not, because the process has high adaptability. Basis on similar experiences in China, the coking CHPP with flexible flow sheet can win more about 22 million RMB per annum than those without suitable flow sheet (Capacity: 3.5 million tons per annum).

If the process is not suitable enough, the net benefits would loss. Additionally, due to the weak adaptability, CHPP would meet with unnecessary shutdown. The worst possibility, CHPP would have another upgrade project without planning.

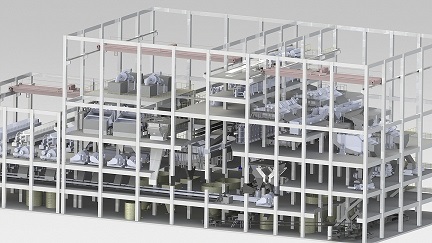

3D Engineering Design of Coal Washing Plant (CHPP, Coal Washery) Click or more 3D engineering design of coal washing plants.

Case Study

Wangzhuang Coal Mine Coking CHPP located in Changzhi, Shanxi Province, it belongs to Lu’an Group which is listed in the TOP 10 coal mining companies in China. Wangzhuang CHPP. Before its upgrade, the capacity is about 0.6MTPA, the major process technology is Jig + Small Cyclone + Flotation + Spiral + Thickener. After upgrade, the capacity designed to be 6.0 MTPA, actually, it could process about 8.0 MT ROM coal per annum. The new process technology is Heavy Medium Vessel (Bath) + First Cyclone + Secondary Cyclone + TBS + Spiral + Flotation + Filter Press + Thickener. Now the operation performance is much better than before.

For better comparison, we convert the capacity into 3.5 MTPA. (Old CHPP & Upgraded CHPP)

3D engineering design of coal preparation plant & Operations and Maintenances Services

Technical & Benefits after upgrade

So, it’s better to visit some similar CHPP projects and discuss more details with professional engineering or technical consulting companies before inviting for tender. It could help to minimize potential risks and save cost. If coal mining companies wants to import equipments from China, it’s better to visit those equipments’ performance in real CHPP (coal washery, coal washing plant, coal handling preparation plant).

Below translation, by Ms. Serena Fu, International Business Manager of HOT Mining Tech. Many translation shall improved to be more professional.

[Engineering Design, the crucial factor of Coal Washing Plant Delivery]

During 2002-2012, the coal washing technologies have been improved rapidly. These changes has promoted the design document’s quality and technology standard of many Chinese engineering company and some state-owned state institute becoming better, also the documents’ content has changed a lot, mainly as follows:

1. More Strict Requirments on Coal Quality Analysis

1.1 The expansion and extension of coal usage

Recently, coal is not only the raw material of power fuel and coking, but also the valuable material of some high-added value industry which could replace the petrochemicals, such as modern coal chemical industry and coal-based compound fuel oil. Some industries such as clean coal technology, coal liquid, coal liquefaction and coal gasification has got good development chance, for example: supercritical, super-supercritical pulverized coal fired boiler, large circulation fluidized bed boiler, coal based syngas to methanol, methanol chemical products(dimethyl ether, acetic acid and the following down-stream product), methyl alcohol made alcohol ether fuel, methyl alcohol made olefin, poly-generation, direct liquefaction, indirect liquefaction, smouldering and Lignite drying quality.

The usage of coal has been greatly expanded and extended. Different coal usage method has different requirement about coal property, which pushes coal preparation engineers to expand the knowledge width.

1.2 More strict requirement towards coal property analysis

The coal property analysis and processing performance analysis plays important role, because it’ one of the basic factors in determining the product orientation and structure after being washed.

1.3 The content of coal property analysis is more comprehensive

Besides the regular industry analysis and elemental analysis, the coal processing performance index analysis, micro coal rock structural analysis, degree of coalification analysis and metamorphic grade analysis shall also be included. The design document shall reflect original data of geologic report. The coal property information listed in the design document sometimes is not complete, and pointless. Mainly reflected in the following questions:

(1) When used as thermal coal, usually lack of some index related to boiler corrosion, such as chlorinity and fluorine content, also some index related to slag removal, such as ash fusion point, clinkering property and dirt property.

(2) When used as raw material of coal chemical industry, usually lack of some important index related to moving(fixing) coal gasification and gasifier efficiency such as machinery anti-crushing intensity, thermostability, convert ratio to COand so on.

[Case Study] Meagre coal in Lu’an coal mine district has low intensity of machinery anti-crushing, and easily smashed during transportation. Some plant in Taiyuan is the lump coal user of this coal mine, which is used as gas generating. During the transportation, the lump coal is smashed, and caused contract disputes. It suggests that the meagre coal in this mine is not suitable for gas generating.

(3) When the coal is applied as liquidation, sometimes lack of vitrinite reflectance parameters related to coal’s micro-coal rock composition, degree of coalification and metamorphic grade, and some indicator reflects the carbon hydrogen ratio, oxygen content, hydrogen content, grindability, coal ash fusibility, flowing temperature and etc.

(4) When coal is applied as the raw material producing the synthesis gas, and the coal gasification processing is the water coal slurry gas flow bed processing, sometimes lack of analysis about coal water slurry.

[Case study] The non-caking coal of some coal mine in Shanxi Yushen coal mine is the raw coal base of indirect liquidation project with 1mt per year capacity for one coal group in Shandong. This processing of this project adopts the Texaco coal-water slurry flow bed, which lack analysis of slurry character. The non-caking coal’s slurry character is very bad, with only 59.5% of the coal-water fluid concentration in lab data, but the indirect liquidation project feasibility study designed coal-water concentration is about 65.0%. Which has many adverse impact on the gasification processing.(With the add of coal consumption and oxygen consumption, the investment has added hundreds of millions)

1.4 The requirement of coal quality analysis is more sophisticated and accurate

Quality characteristics and presentation process performance index is not accurate enough, there is no strict accordance with the various division level coal quality indicators relevant national standards or industry standards to express. It should be noted that these standard dynamic management, with the passage of time and technological progress, all kinds of coal quality division level standards are constantly revise and improve. We must grasp the new "standard."

1.5 The coal type and sulfur content two important factor when to determine the direction of coal products, which cannot be ignored. It is necessary to point out it.

State applies the principles of classification of coal resources and the use of optimal allocation (Industrial Development and Reform Commission [2006] No. 1350 text). Coal type and sulfur content, involving questions of principle relating to national resources and reasonable utilization. According to the State Environmental Protection Administration, the State Economic and Trade Commission, Ministry of Science and January 30, 2002 jointly issued documents (UNCED [2002] 26) the provisions of Article 3.1 of "no new coal seam around stars more than 3% of the sulfur mine"; in "coal, peat geological exploration specification" (DZ / T0215-2002) Appendix E proposed to estimate the amount of coal resources index, the maximum sulfur content of 3%; the national development and reform Commission Notice No. 80 of 2007 "coal industry policy" tenth three also pointed out, "the State applies protective exploitation of special and scarce coals, limiting sulfur, high ash coal resource development." Thus the Ministry of Land and attaches great importance to the project approval countersign these two issues. For example: gas coal (1) Huainan Mining Guqiao and coking coal mines will not be a problem for power generation; (2) high-sulfur coal mine Songzao (St.d> 4.0%) resources, development and utilization of the question whether it is reasonable . National Development and Reform Commission approved the two projects were met Ministry of Land and countersigned in question. Another expert, again demonstrated. So, when designing special and rare types of encounters other purposes or high-sulfur coal resources need to be developed, the need for development and utilization of rationality should be demonstrated. Often they lack the necessary design files such arguments, especially the development of Yunnan, Guizhou, Sichuan area of high-sulfur coal mines.

[Case Study] Guizhou Zhijin coal mine fertilizing overall high sulfur coal seams is one of the main coal quality characteristics of Ida, where the 7th, 23rd floor average sulfur coal were up 4.22% and 4.10%, are sulfur coal.

However, the feasibility study of the occurrence of high-sulfur coal resources Ida mining, the use of reason, necessity lack the necessary proof and elaboration. Guizhou Province is rich in coal reserves, but high-sulfur coal more resources. For example, sulfur fertilizer Tianjing Tian> 3% and 3% of coal reserves almost half and half. So that high-sulfur coal resources are fully rational use is unavoidable reality.

Only from the following three aspects of the grounds of high-sulfur coal mining provide some ideas for the Feasibility Study prepared to consider:

(1) For mining, Sulfur within Ida> 3% sulfur coal and sulfur 3% of the coal resources are staggered symbiotic. For example, a group of three coal, coal seam No. 6-1 average sulfur content 3%, while the average sulfur content of coal seam No. 7> 3%. In the mining process, if not crossed the 7 layers of high sulfur coal mining, continuing the lower part of the coal seam mining, the coal seam No. 7 would have been caving destroyed. Even in average sulfur content 3% in the same coal seam, there is also sulfur> 3% block segment, for example, No. 6 coal seam average sulfur though 2.59%, but the fluctuation range of sulfur was 1.88% - 3.21% of the between. In the mining process, it is impossible not crossed the segment of high sulfur coal mining blocks. In short, the underground mining process is difficult to achieve only low-sulfur coal mining, high-sulfur coal not mined. The reality is that low-sulfur coal mined in the same time, if not high-sulfur coal mining, the high-sulfur coal resources will be destroyed and can not be preserved intact. This is a waste of precious fossil energy resources at once.

(2) For the coal property, in view of the high sulfur Ida sulfur iron ore mainly composed of inorganic sulfur (nearly 80 percent), low content of organic sulfur, which provide a very favorable conditions for washing desulfurization. PRECISE geological report data show that the theory of high-sulfur coal washing desulfurization rate of nearly 70%. 7 wherein sulfur coal can be reduced to 1.32% from 4.22%; 23 coal can be reduced to 1.44% from 4.10%. For this high-sulfur coal mines, the through washing and processing coal in most of the sulfur is removed. Using washing desulfurization power plant boiler flue exhaust desulfurization + combination treatment, fully able to effectively control SO2 pollution of the environment, meet the national environmental requirements, high-sulfur coal mine based rational use of resources provide a viable condition.

(3) In addition to this high sulfur anthracite mine, the other quality characteristics: such as high - especially high calorific value, especially phosphorus, arsenic low, medium ash softening temperature, high thermal stability, high crush strength and other characteristics are in line with high-power electricity coal gasification and quality requirements. From the protection of national resources considerations, the high sulfur anthracite coal mine exploitation should be, and make full use by Comprehensive Utilization.

2. The Coal Product Direction And Structure Need to Be Market Oriented.

The direction of coal products, the product mix should be based on market demand. With the higher demands of the market adaptability, than the initial period of planned economy and a market economy has been a qualitative change. So when the feasibility study report review, the target market for coal products require more precise analysis, user requirements are more implemented, with the general requirements of the target user's coal supply agreement initialed as a support document.

Target market analysis, implementation is important because it is one of the bases of coal products to determine the direction and positioning of the product mix.

2.1 Determine the base of coal product direction and structure.

Coal product direction and positioning of the product mix is mainly based on two: First, coal quality characteristics; second is the market demand. Target market is not implemented, given the direction of the product is not accurate, when completed will result in passive and losses.

[Case study] Jibei Mine coal preparation into the wash of the main mine production No. 3 coal seam. 3 inherent low ash coal seam, and Yanzhou coal mining area within the gray similar. However, the yield of light density material level much lower than Yanzhou. Now a two coal Yanzhou Coal and 3 # 3 # coal in Jibei Mining contrast as follows:

Yanzhou(3#) Jibei Tangkou(3#) Jibei Xuchang(3#)

Accumulated float coal ash content % 8.54 8.52 8.57

Floating rate cumulative production of coal content% 87.32 70.43 71.88

Thus, the economic coal mine in the north under the production of low ash product, the yield is much lower than Yanzhou Coal Mining (lower by about 16 percentage points), its cost may be much better than Yanzhou good. Coupled with extremely rich East China gas coal reserves, and the local market for coking coal is used with gas coal and coking coal demand is very limited. Jibei mine production of low ash coking coal product can not be with the neighboring gas coal Yanzhou quality competition, so after the election ash products should not be set too low. According to the economic analysis of a Coal Mine in the North # 3 coal drifting data obtained when producing high-quality thermal coal ash ≤12%, the biggest increase in its yield. Than the production of 9% ash coking coal product, increase the annual production of about 180,000 tons, an increase of about 20 million yuan profit. Therefore, it is recommended Jibei mining coal preparation product positioning, should be to produce a high-quality thermal coal ash ≤12% based.

[Case study] Weakly caking coal mine in Shaanxi Province Huangling a mine, although having low internal waters, low ash, low sulfur, high calorific coal quality characteristics, however, is not the ideal blast furnace injection of coal. Higher due to evaporation (Vdaf = 33.75% in the case of high volatile) points, points higher phosphorus (Pt.d = 0.067% in the case of phosphorus), low ash content can be used as injection coal particles under high temperature conditions skeleton Al2O3 content (only 21.67%), as a blast furnace injection of coal is not ideal.

Injecting Coal limited domestic market demand, the need for blast furnace injection of coal 20.00Mt / a or so. The coal mine and coal quality reasons regard as blast furnace injection of coal is not ideal, as compared with neighboring provinces such as mine in Jincheng, Yangquan mine anthracite, lean coal Lu'an Mining, the quality gap is large, as a blast furnace blowing coal market less competitive, market difficult to open. In addition, weakly caking coal coking coal market as little more amount. Therefore Huangling II coal mine blast furnace with coke and injection coal as the main product direction, substantially all coal washing, the principle of low-ash coal production and processing products, is endless reasonable.

It is understood that during the preparation plant test run, because blast furnace injection of coal and coking coal market push is not open, the end of the coal product sales are sluggish, resulting in the Coal Dense Medium Separation System and interference slime bed sorting system long idle, resulting in waste.

This case fully proved coal quality conditions and market demand has a significant impact on determining the correct product orientation, to develop a reasonable product structure, with the typical sense.

3. The Common Questions in the Market Analysis of Feasibility Study

(1) Market analysis covers international and domestic, vague content, and research itself is not closely linked.

(2) The target user market analysis is not specific enough; the lack of end-user demand for coal intent agreement text.

Detailed analysis of the target market and user text coal supply agreements are one of the important projects of the National Development and Reform Commission, it is indispensable, should not air to air. (The most simple truth: If no users, there is no need mining, countries that do not promote the use of the newly opened mine to run existing product market, which is a waste of resources.)

Contact us:

Serena Fu

Kira Zhang

serena.fu@hot-mining.com

kira.zhang@hot-mining.com

Skype

Serena20140924

kira.zhangjing

Please feel free to give your inquiry in the form below.We will reply you in 24 hours.