Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

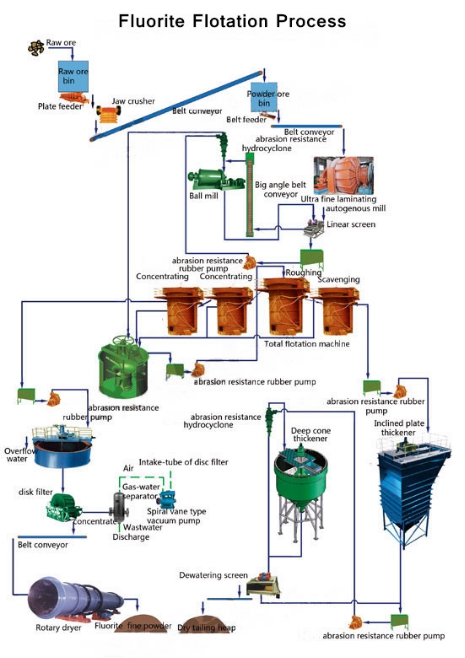

Fluorite Flotation Process

Process Introduction

Process methods of fluorite ore are gravity separation and flotation. Mineral processing equipment includes gravity separation equipment and flotation equipment; gravity separation equipment: jig. Only jig can deal with the coarse fluorite ore. Fluorite flotation equipment includes crusher, ball mill, flotation machine etc. Jaw crusher is the primary crusher. It is used in fluorite coarse crushing process. Cone crusher is the fine crushing machine used in fluorite processing plant. After fluorite crushing process, fluorite is less than 15mm. Grinding mill used Ford fluorite processing. Ball mill is the most commonly used fluorite ore dressing machinery. After grinding, fluorite is less than 0.074mm. In order to get concentrates, re-grinding process is essential. The final size of fluorite powder is usually 100 meshes, 200 meshes, 400 meshes.

Application

Fluorite flotation process is applied for refractory fluorite with complicated properties such as high mud content, impurity containing, fine particle distribution etc. Our fluorite flotation process has many advantages including automatic controlling, high efficiency, safety, fast and low energy consumption.

Process Description

Fluorite ore processing

Fluorite ore processing methods which is one roughing repeatedly choice,as a collector agent rougher with oleic acid or its substitutes, to a mixture of sulfuric acid with an acidic waterglass-containing substanceinhibitor, a sulfuric acid with an acidic waterglass ratio is 1:0.5 to 1:2, the joint used in an amount of 0.5 ~ 1.5kg / t ore. The present invention provides fluorspar addition to calcium beneficiation process has in addition to the high efficiency of calcium, the process is simple, low-cost advantages can be selected from the high calcium fluorite ore grade fluorite concentrate with a low content of calcium carbonate.

Natural fluorite fluorescent paint

A natural fluorite fluorescent paint process, the process of dressing - crushed - preparation - mixing - sintering. The present invention has a simple process and low cost to meet the arts and crafts paint and various fluorescent effect required items need.

The preparation method of fluorite flotation agent

A process for the preparation of fluorspar flotation method, the crude intermediate product produced with oleic fatty acids or mixed fatty acids as raw materials, added thereto weight of the fatty acids of 3% to 15% by weight of concentrated sulfuric acid, so that the occurrence of sulfatedreaction, again in the reaction product by weight of fatty acid weight the beneficiation of 0.4% to 3% of foaming agent accompli product. The present invention provides a method of producing low-cost production fluorite floating selection collectors collecting capacity, water-soluble, dispersible, suitable for room temperature and low flotation fluorite.

Fluorite flotation adjusting agent composition

A flotation of fluorite ore processing method, it is granted a patent improvements 87,105,202 No.Flotation fluorite mineral acid jacketed plus synergist modifier. Any one of the water glass of the present invention, the addition of acid and the acid composition of one or more soluble salt mixture composition for the adjusting agent, and the formation of the composition series, can be used sulfuric acid, hydrochloric acid, nitric acid, oxalic acid, acetic acid kinds of acids and the corresponding salts, the combination ratio range of waterglass and acid.

Carbonate - fluorite flotation separation method

The present invention provides a carbonate - fluorite ore economic effective flotation separation method, especially for the high carbonate content of the flotation separation of fluorite ore. The key is to choose the carbonate minerals inhibitors - acidified water glass processing drug measures in the conventional process conditions, carbonate and fluorite achieve high purity sorting.

Flotation fluorite ore processing

The present invention uses a mixture of acid, alkali and synergist as a modifier, oleic acid or oak sodium oleate as collector, the process for the composite circuit in a near-neutral under normal temperature conditions fluorite oreflotation of fluorite concentrate obtained a high recovery rate, product quality, low impurity, pharmaceutical consumption, low cost, suitable for all kinds of fluorspar concentrator applications.

Process Flow

Case

A fluorite dressing plant in Guangzhou, fluorite and quartz are the main minerals, and there is a small amount of pyrite, sericite, chlorite, calcite, barite, clay minerals and various sulfides. Dissemination size of fluorite is not epigranular, particle size ranges from 0.01mm to 40mm, general is 1 ~ 3 mm, fluorite and quartz coexist. Under the condition of 87% of grinding particle size is -0.074mm, adopting fluorite flotation process, flotation temperature is 36 ~ 25℃, taking H111 as the collector to be added in the rough concentration, secondary concentration and fourth concentration. Superfine fluorite ore concentrate can be obtained after a rough concentration and six times’ concentration. The concentrate contains CaF2 98.96%, recovery rate is 91.81% (concentrate contains SiO2 0.55%).

Contact us:

Serena Fu

Kira Zhang

Teresa Zheng

serena.fu@hot-mining.com

kira.zhang@hot-mining.com

teresa.zheng@hot-mining.com

Skype

Serena20140924

kira.zhangjing

teresa.zheng123