Company:Chengdu Cobalt Mining Co., Ltd

Email: sales@hot-mining.com

Phone:+86 28 83311885

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Application of MES Process® Series Color Sorter in Fluorite

1. Introduction to Ore Color Sorter

In the mining sorting industry, the ore color sorter is also called sensor-based sorting technology. Optical color sorters (CCD color camera) combine X-ray sorting technology and NIR (near infrared spectrometry) to pick out the impurities of ore, minerals, stone and sand products, or separate ore into two or more categories.

The ore raw materials containing some valuable minerals mined from the mine can be used in engineering fields such as construction industry, cement industry and gravel industry after step-by-step processing such as crushing, grading, color separation and grinding. Among them, the preparation of ore is particularly important. After color sorting, the ore has high purity and uniform color, which greatly improves the utilization rate of ore and doubles its value.

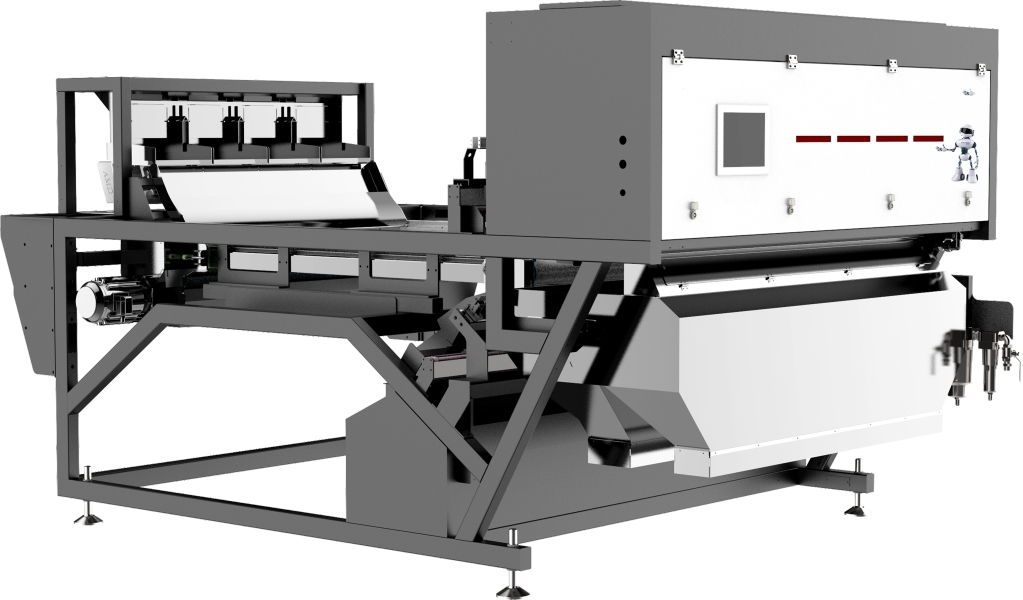

2. Working Principle of Ore Color Sorter

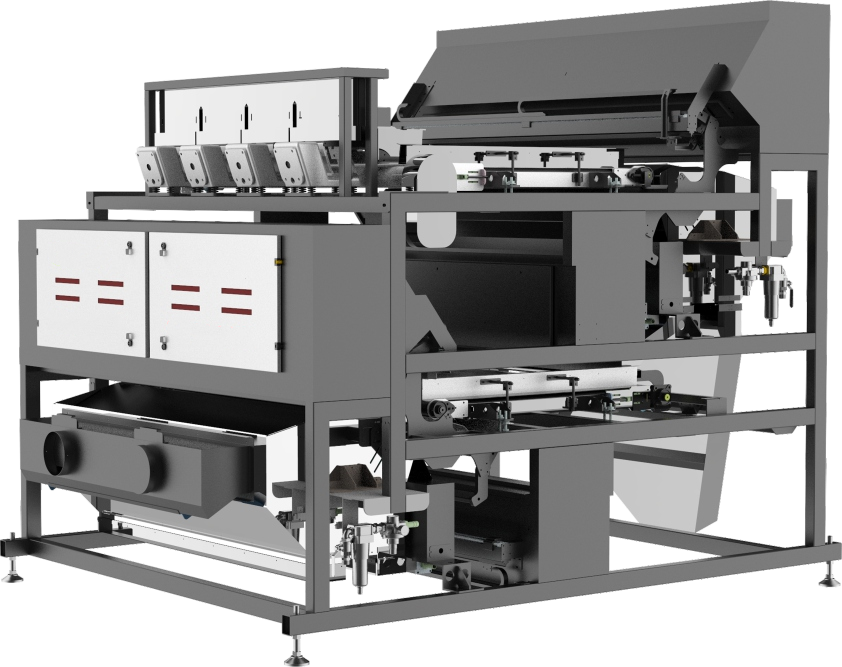

MES Process® Ore Color Sorter developed by HOT Mining separates selected materials according to different colors through high-resolution sensors based on the difference of optical characteristics of materials and the principle of photoelectric detection, so as to realize automatic sorting. There are light source, high-speed camera and air jet nozzle above the material. The air jet nozzle sprays high-pressure air to change the running track of the material, so as to realize the entry of good and bad materials into different receiving areas. At present, it has been successfully applied to the beneficiation and purification of non-metallic minerals such as quartz, feldspar and fluorite.

Working Principle of MES Process® Ore Color Sorter

3. Advantages of MES Process® Ore Color Sorter

·Double layer sort, high sorting accuracy

·Support dry or wet separation to realize continuous production

·Remote control

·Customized algorithm, bring out ratio is smaller

·The real-time display of physical image can separate a variety of ores of different sizes

·Low consumption, high frequency solenoid valve, with anti dust environment

4. Fluorite Color Sorting Effect

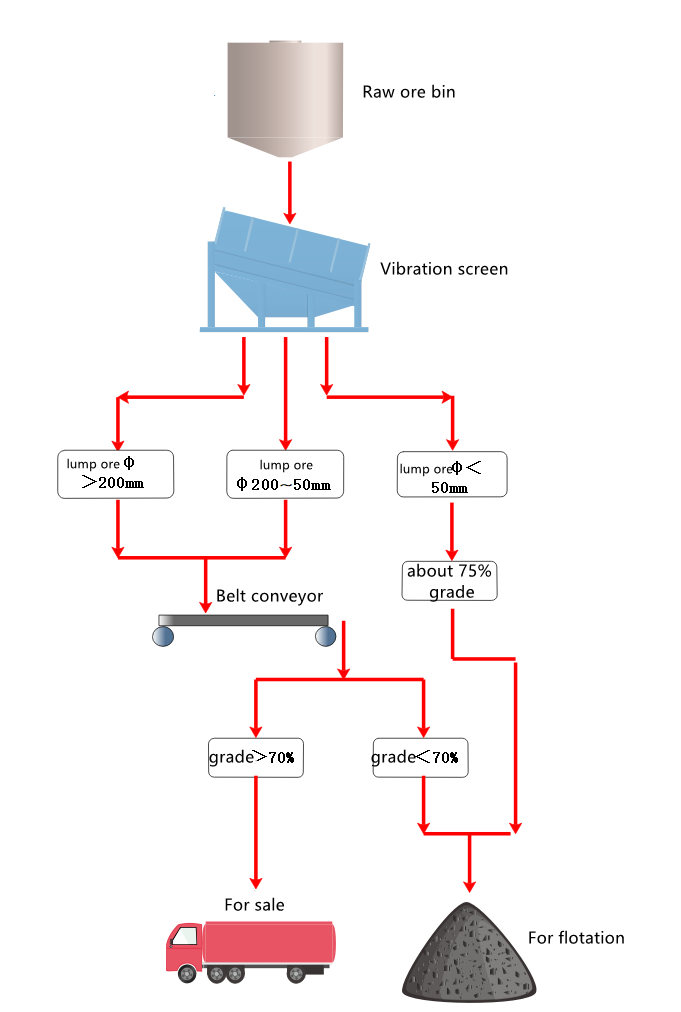

4.1 Traditional manual sorting of fluorite ore

The ore in the raw ore bin is divided into three specifications of > 200mm, 200mm-50mm and < 50mm by vibrating screen. Among them, those with block size > 200mm and 200-50mm are manually selected. After removing waste rock, those with CaF2 content > 70% are directly sold, and those with CaF2 content < 70% are supplied to flotation plant for flotation. Those with block size < 50mm are also supplied to the flotation plant for flotation.

Process diagram of traditional manual sorting of fluorite ore

After years of manual selection, the proportion of three specifications: block size > 200mm, 200mm ~ 50mm and < 50mm account for 30% respectively, and waste rock accounts for 10%.

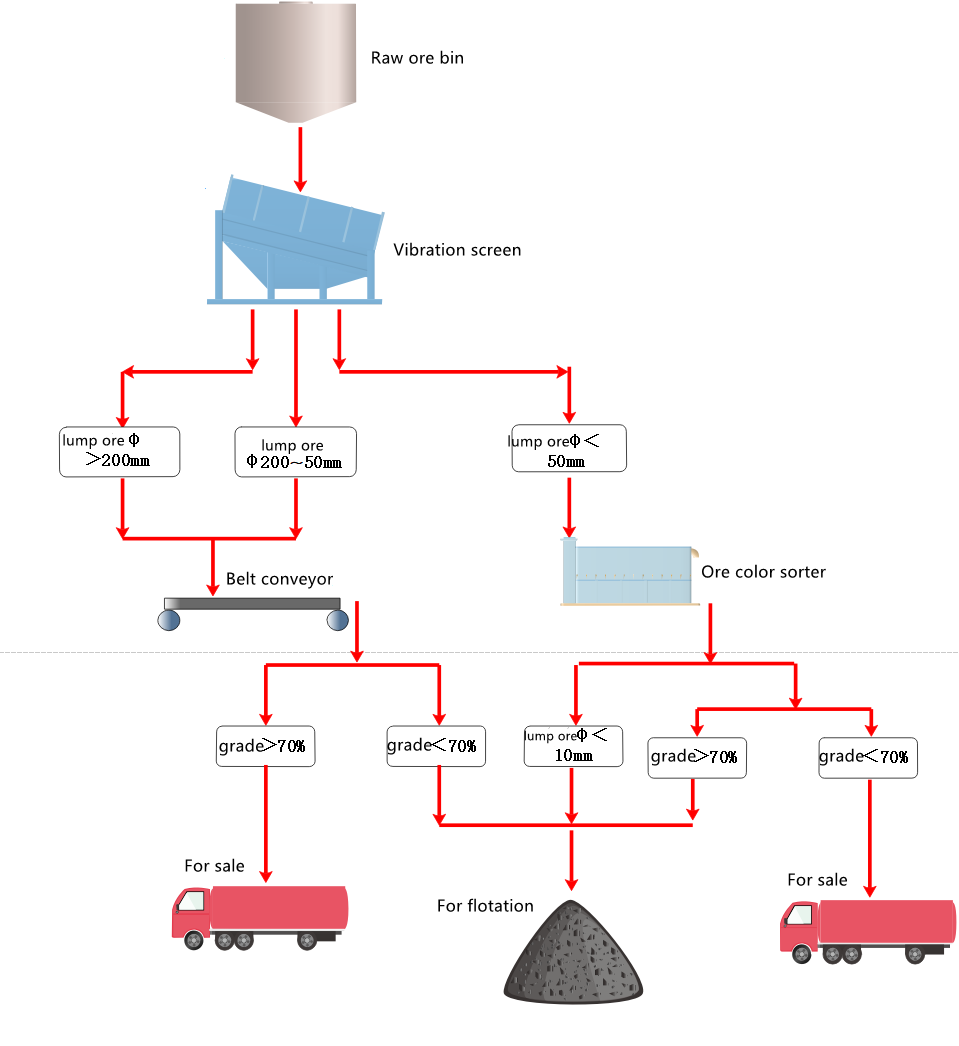

4.2 Fluorite manual + color sorting process

Guizhou 9X Minerals Co., Ltd has introduced crawler MES Process® Ore Color Sorter to be applied to the barite fluorite mine of the company, which is specially used for color separation of small ores with a block size of 10mm-50mm that cannot be selected by hand.

Fluorite ore manual sorting + color sorting process diagram

Based on the traditional manual sorting process, the fluorite ore with block size less than 50mm that cannot be directly selected by hand is again screened through the secondary vibrating screen, which is divided into two specifications: block size less than 10mm and block size of 10mm-50mm. The fluorite with block size less than 10mm is directly sent to the flotation plant for flotation, and the fluorite with block size of 10mm-50mm is color selected by the ore color sorter.

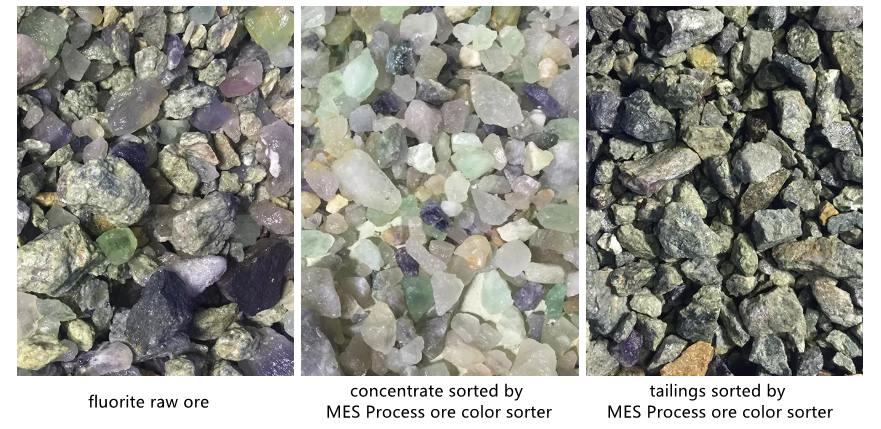

The raw ore with block size < 50mm accounts for 30%, about 100 tons / day. After screening by secondary vibrating screen, about 50 tons of raw ore with block size of 10mm-50mm can be screened. Then through the color sorter, about 25 tons / day of good ore can be selected every day, and its CaF2 content reaches about 80%. The color sorter tailings are about 25 tons / day, and the CaF2 content reaches about 50%, which are sent to the flotation plant.

Effect of fluorite sorted by ore color sorter

After a long time of operation, the MES Process® Ore Color Sorter has brought considerable economic benefits. In the follow-up, most manually selected ores can be changed to color separator beneficiation, and machines can replace people, reduce personnel, and increase the economic and social benefits of the enterprise.

Contact:

Tiffany Chen

+86 18282103350

tiffany.chen@hot-mining.com