Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Technological Transformation and Application Practice of a Gold Mine in the West of Henan Province in China

Abstract

This paper systematically expounds the basic characteristics of a gold mine in western Henan in China, such as ore composition, ore type and ore characteristics. In view of the problems existing in the mineral process and production, combined with the actual production, the original mineral process is reformed and optimized from the aspects of ore crushing, grinding, particle size classification, flotation process, equipment transformation and agent system, so as to realize the large-scale production of the mineral processing plant. It can improve the gold concentrate grade and the total gold recovery rate, reduce the production cost of beneficiation, and lay an important foundation for the comprehensive economic benefit and sustainable development of the gold plant.

A gold mineral processing plant in the west of Henan Province in China was built in the 1990s with a design scale of 30000 t/ year. The process of "all slime cyanidation and carbon leaching" is adopted in the design. Due to the high hardness of the gold ore mined and the aging of the mineral processing equipment, the original gold separation process has been difficult to meet the current separation requirements, resulting in various technical and production indicators difficult to meet the standards. In view of this phenomenon, the technical personnel of the plant refer to the experience CD-5 of other gold concentrators and optimize the original beneficiation process in combination with the actual situation on site. The results show that the new beneficiation process not only effectively reduces the consumption of cyanide, but also greatly improves the beneficiation capacity and gold recovery rate.

1. Original beneficiation process, indexes and existing problems

The ore crushing adopts the "two-stage one closed circuit" process for crushing. The raw ore is primary crushed to form a ore particle of - 25 mm for distribution, and then through the pre inspection and screening system, the over-sized screening material enters the grinding system, the over screening material enters the fine crushing process, and then returns to the pre inspection and screening system for secondary screening; the grinding product enters the inspection and classification process flow, and the overflow material of the classifier enters the hydrocyclone. The underflow miscarriage returns to the grinding system for secondary grinding, in which the overflow product concentration of the classifier (the mass fraction of the overflow product is controlled at 28% ~ 32%, and the ore particles with particle size of - 0.074mm account for 67% ~ 75% of the total ore particles); after the separation by the hydrocyclone, the overflow miscarriage enters the flotation process, and the flotation adopts "one primary crushing, two scavenging and two cleaning", that is, the overflow of the hydrocyclone entering the flotation process. The products are first roughed, and the overflow and the bottom runoff from the roughing shall be cleaned twice, and the bottom runoff shall be cleaned twice; the concentrate shall be dehydrated by the thickener and the filter press respectively, and the resulting concentrate shall enter the concentrate bin, and the tailings shall be pumped to the tailings bin by the slurry pump after flowing automatically.

The agent system used in the original mineral process is 0.16 kg / T butyl xanthate, 0.07 kg / t butylammonium black agent and 0.03 kg / t terpineol oil; the beneficiation index is the annual processing capacity of 30000 T, the gold grade of raw ore, concentrate and tailings (the mass fraction of gold is 2.25, 77.26 and 0.46 g / t respectively, and the gold recovery rate is 80.06%).

There are many problems in the original beneficiation process. The analysis shows that there are three main problems: first, the hardness of the gold ore is relatively large, and it is unreasonable to use the "two-stage one closed circuit" process for crushing, and when the screening materials enter into the crushing equipment selected for fine crushing in advance, the load of the equipment during operation is large, which affects the processing capacity; second, the ball ratio of the ball mill is unreasonable when grinding the ore. It is beneficial to the grinding of ore with high hardness and easy to damage the lining plate of the ball mill; third, the unreasonable reagent system, large consumption of various reagents and high gold content of tailings are not conducive to improving the benefit of the concentrator and environmental protection.

2. Beneficiation process transformation and application practice

2.1 Improvement and Optimization of Beneficiation Process

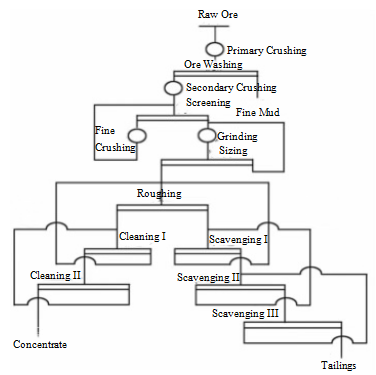

In view of the disadvantages of the original mineral process and a series of problems occurred in the mineral process, the technical personnel combined with the actual situation of the site to transform and optimize the original mineral process, that is, to change the original "two-stage closed circuit" of ore crushing into "three-stage one closed circuit ore washing" process, in order to reduce the particle size of ore crushing and improve the beneficiation processing capacity; to change the grinding concentration of the original ball mill (the quality of solid materials contained in the pulp Increase the concentration by about 10%, that is,set the grinding concentration to about 79%, and appropriately increase the proportion of small and medium-sized steel balls in the ball mill; increase the overflow concentration (mass fraction of light materials) of the spiral classifier to 35%, and the particle product of - 0.074mm accounts for more than 65%, at the same time, reduce the operation load of the ball mill by properly reducing the overflow weir of the classifier; properly optimize the flotation process, and increase one-time tailings scavenging. The concentration is changed to "one primary crushing, two scavenging and two cleaning" to improve the total recovery rate of gold. The improved beneficiation process flow is shown in Figure 1. The dehydration process is unchanged and the concentrate moisture is reduced. The agent system is optimized to reduce the use of technical agent. The agent system is determined to be 0.12 kg / t butyl xanthate, 0.06 kg / t butylammonium black agent and 0.02 kg / t terpineol. At the same time, lime is added to determine the lime consumption is 0.5 kg /t and 0.5 kg/t lime. Adding place is determined as ball mill, which can reduce cyanide consumption and improve alkali treatment capacity.

2.2 process Application Practice after Transformation

After the transformation of the original beneficiation process, all indexes have been optimized, and the beneficiation treatment capacity has been increased to 100000 t/year, more than three times of the original treatment capacity; the concentrate gold grade (the quality fraction of gold has been increased to 81.52 g/t, which is 4.26 g/t higher than the original process; the tailings gold grade (the quality fraction of gold) is 0.31 g/t, which is 0.15 g/t lower than the original process; the gold recovery rate has been increased to 86.13%, which is more than the original process. The consumption of butyl xanthate, butylammonium black drug, terpineol oil and other chemicals decreased.

3. Conclusion

Combined with the actual situation, the original beneficiation process is optimized, the beneficiation scale is expanded, the total gold recovery rate is increased, the production cost is reduced, and the comprehensive economic benefit of the enterprise is improved. In the new process, the equipment used in each process is optimized and improved to give full play to its optimal performance and realize the large-scale management and intensive management of the equipment. In the beneficiation process, an automatic control system can also be added according to the actual situation to ensure that the system is always in a stable treatment state, which can effectively control the use of various chemicals, reduce the labor intensity of operators and ensure the optimization of the process.

Contact HOT for your gold roject or other minerals:

Name Email Tel/Whatsapp

Teresa teresa.zheng@hot-mining.com +86 15281626323

Eric eric.liu@hot-mininf.com +86 13699096165