Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Barite Mineral Processing

Process Introduction

Barite is a fragile material and the shape of it is like a tube. The Barite Mineral Processing that HOT Mining offered can make our customer satisfied. The processes we can offer are gravity separation magnetic separation and flotation. We are your best choice.

Application

The process of high brightness micro powder and superfine powder

The production of barium salt

Process Description

Gravity Separation:

For the gravity separation of barite, the process of HOT Mining is crushing, screening and jigging. Then the high grade (over 80%) concentrate will be produced. Jig is the main equipment for the separation and purification of barite ore, which is energy saving, high efficiency, and environment protection. In the process of crushing, HOT Mining uses jaw crusher and applies two-stage crushing process. In the process of screening, HOT Mining uses simple and useful circular vibrating screen, which also have the features of large capacity, high efficiency, and convenient operation. It is very suitable for screening of barite ore. In the process of jigging, HOT Mining applies two kinds of jigs to respectively separate the coarse and fine granularity of barite material.

Magnetic Separation:

HOT Mining usually applies wet magnetic separation to beneficiate some iron-bearing mineral, like siderite, which applies to barite ore that is used in barium-based medicine requiring low iron barite.

Floatation:

As for the barite with fine particle size and gravity tailings, HOT Mining applies process of floatation. According to the different adsorption manner, HOT Mining uses some anionic collector, like fatty acid alkyl sulfate, alkyl sulfonate, or cationic collector, like amide collectors to do the floatation for barite ore.

Case

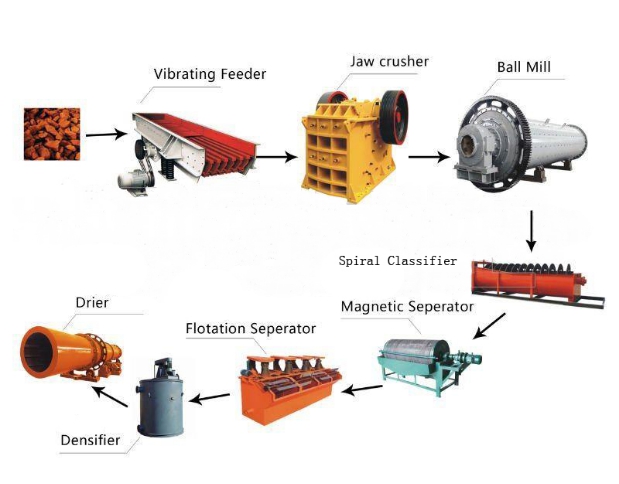

For example, HOT Mining had a project in Guizhou Province. We use machines like a vibrating feeder, a jaw crusher, a ball mill etc to make up a barite mineral processing system which has a daily processing capacity of 1000 tons. These machines are used for processing of coarse or medium barite particles. Our customers are satisfied with our whole system.

Process Flow

Contact us:

|

|

Serena Fu |

Kira Zhang |

Teresa Zheng |

|

|

serena.fu@hot-mining.com |

kira.zhang@hot-mining.com |

teresa.zheng@hot-mining.com |

|

Skype |

Serena20140924 |

kira.zhangjing |

teresa.zheng123 |