Comparison Between TBS, Slime DMC and Spiral Separator

TBS (Teetered Bed Separator) is mainly used for the separation of coal with a particle size of 1 ~ 0.25mm. As the mainstream coarse slime sorting equipment, it has the characteristics of simple structure, low operating cost, and low maintenance. However, because of its simple structure, its large number of manufacturers and different products make TBS have different reputation in the field of coal preparation. This article will analyze and compare the sorting effect of three kinds of equipment, TBS, slime DMC (Dense Medium Cyclone) and spiral separator.

The separation effect of coarse coal slime in laboratory

First of all, the above three kinds of equipment are heavy sorting equipment. Generally, the comparison of the three sorting effects needs to be performed under the same prerequisites. However, the actual coal preparation plant does not use the three simultaneously. In terms of laboratory sorting results, the highest sorting effects is slime DMC, followed by TBS, and finally the spiral separator.

“The spiral separator has a high separation density, so it is widely used in power coal preparation plant.” This sentence shows that after spiral separation, the ash content of clean coal is high, which cannot meet the ash content requirements of clean coal. In fact, the separation density of spiral separator can be adjusted. The root cause of the above problems is the poor separation effect of the spiral. But in some cases, for example, when the feed selectivity is good and the product ash content requirement is not high, the coal preparation plant can also choose the spiral separator with lower price.

Then let's look at the practical separation effect of free-flow three-product DMC.

The practical separation effect of free-flow three-product DMC

The successful research and development of 1. free-flow three-product DMC has made great contribution to the domestic coal preparation industry. Many reports have pointed out that the separation lower limit of this equipment has reached 0.25mm.

In fact, the application of the three-stage coal preparation process of DMC + coarse coal slime + flotation shows the lower limit of the separation of most free-flow three-product DMC cannot reach 0.25mm, that is to say heavy medium contains ash. But there are also a few parts up to 0.25 mm. But there are a few parts that reach 0.25mm.

The nature of this difference is the slime content entering the DMC. When the slime content is large, the volume concentration of the heavy medium suspension increases rapidly, and the viscosity also increases significantly. Generally speaking, the separation time of the fine coal particles and vermiculite particles in the DMC does not exceed 5 s, and only the particles that have a density close to the separation density have a longer residence time. When the viscosity of the suspension increases, the sedimentation speed of the particles in the centrifugal field decreases, and the particles have left the DMC before they are sorted.

A large part of the slime that has entered the free-flow three-product DMC has not been effectively sorted, which is a waste of the processing capacity of the DMC. If the desalination step is increased, the processing capacity of the three-product DMC will be increased by at least 30%. This is very significant for reducing the median consumption of coal power per ton. In addition, it is generally believed that coal with a coal slime content of less than 10% is directly separated by heavy media, and coal with a coal slime content of more than 15% should be de-slimized, which is the consensus of the current coal preparation technology.

In addition, when the slime content is less than 10%, the viscosity of the suspension is low, which is conducive to the sedimentation of fine particles. Therefore, when the slime content is small, the lower limit of the separation of the three-product DMC reaches 0.25 mm. Is possible.

The practical separation effect of slime DMC

The above laboratory results show that the slime heavy media sorting has the highest accuracy, but why do many coal preparation plants stop or remove the slime heavy media system?

It can be seen from the experiments that the actual lower limit of the slime DMC did not reach 0.125mm. The ash of 0.25-0.125mm particle size in the overflow has exceeded the standard, and it is quite different from the ash content of 0.5-0.25mm particle size, which indicates that the lower limit of the sorting of the slime DMC is higher than 0.125mm, which does not reflect its Choose the advantage of lower limit. This sort of particle size range TBS can also be completely achieved.

The main reasons are: First, the slime heavy medium requires a very fine particle size, which should generally be lower than the 1/8-1/10 of the lower limit. That is, the lower limit of sorting is 0.25mm, and the medium is required to be below 0.02mm. At present, even if the classification effect of the large cyclone is used to increase the proportion of fine-grained medium in the slime heavy medium suspension, it is far from the required medium Granularity, sorting effect is greatly discounted.

Secondly, the two most important factors affecting the slime heavy media sorting are the feed pressure and feed density. The stability of the slime heavy medium is affected by the diversion of the large-diameter cyclone, which causes its pressure and feed density to be unstable, which affects the separation effect. Therefore, the industrial sorting accuracy of slime DMC is far worse than that of laboratory. In this case, it is difficult for slime reintroduction to outperform TBS.

On the other hand, from the current coal preparation process, the feed of slime heavy medium must be the diversion under the arc screen of clean coal. If the desliming process is adopted, there seems to be no place available for slime heavy medium. TBS can be used in both desliming process (separation of the bottom of desliming screen) and non desliming process (separation and concentration of clean coal magnetic tail). Therefore, the application of TBS is more flexible.

This is the main reason why domestic coal preparation chooses to discard the slime and use TBS.

Two-product TBS and three-product TBS

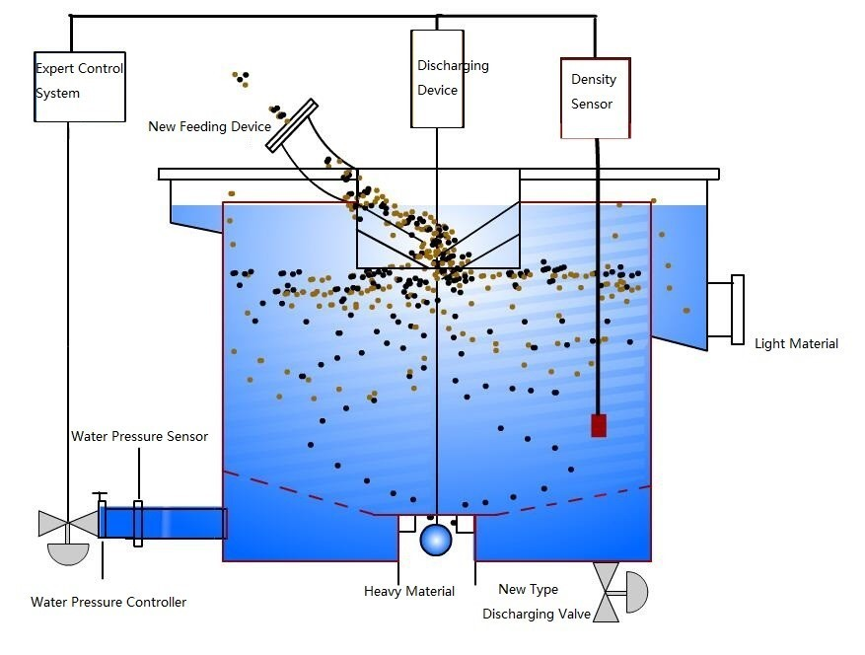

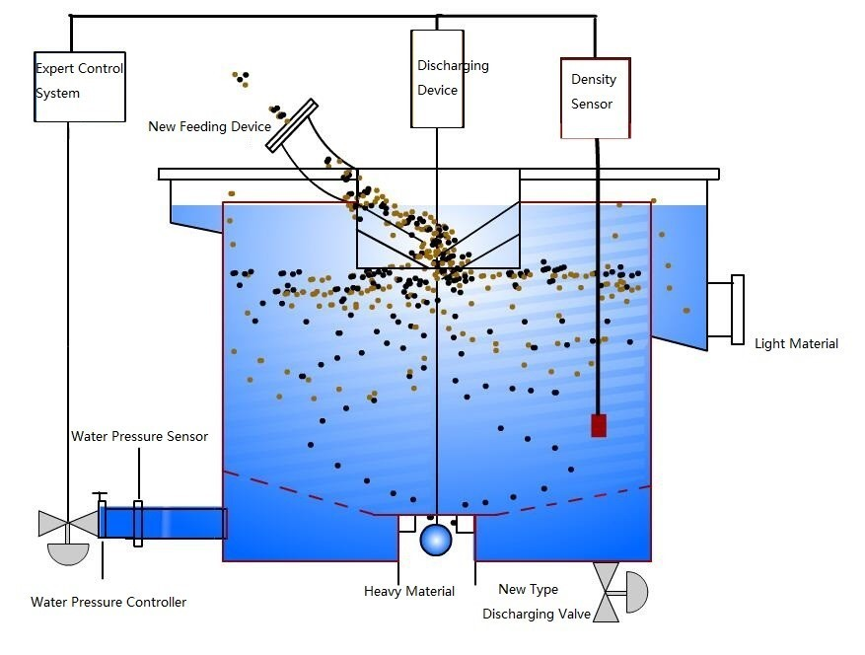

The best feeding range is 1-0.25mm, the separation density is 1.4g/cm³-1.9g/cm³ adjustable, automatic control, low power consumption. " This is a common understanding of TBS. In fact, TBS has its disadvantages.

1) Narrow sorting size range,which is 1-0.25mm. However, from the perspective of separation and dehydration by increasing the particle size, it does not make much sense to increase the particle size of the feed to more than 1mm. After all, the effective lower limit of the DMC can reach 1mm and the separation accuracy is high. It is also difficult to recover particles below 0.25mm with a slime centrifuge. However, if the lower limit of sorting can be reduced to 0.1mm, the flotation feed volume can be reduced. After all, the cost of reselection is 1/3 to 1/4 of the flotation.

2) Clean coal (overflow) often contains high-ash fine mud. Because of the existence of the rising water, the high-ash fine mud will definitely enter the overflow. If the removal of high-ash fine mud in the overflow is not well controlled, it may easily cause the final clean coal ash to exceed the standard. However, this can be completely solved through the combination of processes.

The measures that TBS can use for desliming are as follows: desliming before sorting (one of the functions of the original coal slime hydraulic classification cyclone, the underflow concentration is controlled to at least 35% (about 400g/L)), and the desliming after sorting Mud, (The TBS overflow is dewatered by a hydrostatic cyclone first, and the underflow enters the curved screen for dewatering and dewatering, and the screen then enters the centrifuge for dewatering and dewatering.)

3)Coal is easily carried in the tailings. For the existing two-product TBS, some people think that the coarse-grained clean coal ran into the tailings because the rising water flow was small. The method of increasing the upper water flow was adopted. It can be said responsibly that this is totally wrong. To control the tailings coal, it is necessary to control the size and density settings of the rising water.

The newly developed three products TBS and its supporting technology can solve the problem of tailings coal. The advantage of the three products is to keep both ends, that is, clean coal ash and lime. Then the middle coal ash content of the product is between 15% and 25%. Where to go for this part of materials?

First of all, it should be understood that this part of the coal contains a large amount of low-ash clean coal. If it is directly mixed with heavy medium coal, it will inevitably reduce the recovery rate of clean coal. Proposed by Professor Li Yanfeng of China University of Mining and Technology and successful industrial practice is: after pre-dehydration of the coal in the three products TBS, it enters the mixing tank and is pumped into the non-pressure three-product DMC sorting through the mixing pump , No pressure changes to pressure. Because the coal content in this part is insignificant compared to the medium of more than 1,000 cubic hours per hour, the impact on the heavy media system is minimal. Facts have proved that both heavy ash and TBS ash can reach the target.

In summary, the three product TBS and its supporting technology will have broader application prospects.

Contact us for your coal washing plant proposal:

|

Name

|

E-mail

|

Tel/WhatsApp

|

|

Tari

|

tari.wang@hot-minng.com

|

+86 15927439651

|

|

Teresa

|

teresa.zheng@hot-mining.com

|

+86 15281626323

|

|

Kira

|

kira.zhang@hot-mining.com

|

+86 15281051932

|