The Most Practical Technology in Coal Preparation Plant

Ten common faults of screening machine and their solutions

Fault 1: screen does not vibrate

Phenomenon: the motor only hums and does not start

Treatment: check the motor, check the vibration exciter, and deal with it.

Fault 2: exciter overheating

Phenomenon: the temperature of exciter exceeds the specified temperature

Treatment: check the oil, oil quality and oil quantity, check the bearings and gears, and replace the exciter if there is any problem.

Fault 3: high vibration

Phenomenon: the sound is loud in steel structure support

Treatment: check whether the fixed steel parts interfere with the screen body, whether there is material accumulation on the chute, whether the spring is damaged, and deal with it accordingly.

Fault 4: abnormal sound

Phenomenon: abnormal sound during operation

Treatment: stop the machine and check whether the spring is damaged, whether there are loose parts, whether the exciter cover is damaged, whether the bearing is damaged, whether the exciter gear is damaged, and make corresponding treatment.

Fault 5: too much material under screen

Phenomenon: too much material under screen

Treatment: check the screen plate for wear or breakage, and replace it.

Fault 6: the material on the screen is smaller than the material through the screen

Phenomenon: the material on the screen is smaller than the material through the screen

Treatment: insufficient water spray or clogged sieve plate hole, increase water spray volume or increase the number of spray nozzles or adjust the spray angle, clean or replace sieve plate.

Fault 7: uneven incoming materials

Phenomenon: the thickness of left, middle and right of screen material is not equal

Treatment: the foreign matters in the feeding part are blocked, and stop for cleaning.

Fault 8: rubber connecting plate damaged

Phenomenon: the rubber disk has cracks or noise here

Treatment: check whether the connecting shaft is in a straight line, readjust and replace the connecting disk.

Fault 9: rail seat beam broken

Phenomenon: abnormal sound under screen surface

Treatment: check the rail seat beam. If the broken rail seat beam does not contact the girder, repair welding can be conducted in case of emergency treatment; replace the rail seat beam.

Fault 10: irregular motion of screen machine

Phenomenon: abnormal screen vibration

Treatment: check whether the spring is damaged, whether the screen plate is loose, whether the screen surface is blocked by material accumulation, whether the material flows to one side of the screen machine, whether the beam screen side is broken, and make corresponding treatment.

Five common faults of crusher and their solutions

Fault 1: Super granularity

Phenomenon: lots of coarse coal

Treatment: check whether the crusher tooth plate is broken, whether the tooth of the tooth plate is broken, whether the tooth plate is worn, and replace the tooth plate.

Fault 2: can not be broken

Phenomenon: the motor rotates, the reducer rotates, and the coal overflows from the crusher

Solution: cut off the power and check the coupling from reducer to crusher.

Fault 3: shutdown in operation

Phenomenon: locked rotor alarm

Treatment: check whether there is hard blockage in the crusher after power failure, and check whether the locked rotor switch is normal, and deal with it.

Fault 4: main bearing temperature too high

Phenomenon: the temperature of main bearing exceeds the specified temperature

Treatment: check the amount of grease and pollution, check whether the bearing is damaged and deal with it.

Fault 5: reduced processing power

Phenomenon: the motor rotates, the reducer rotates, and a small amount of coal overflows from the crusher

Treatment: check whether the hydraulic coupling leaks is damaged, and then handle it.

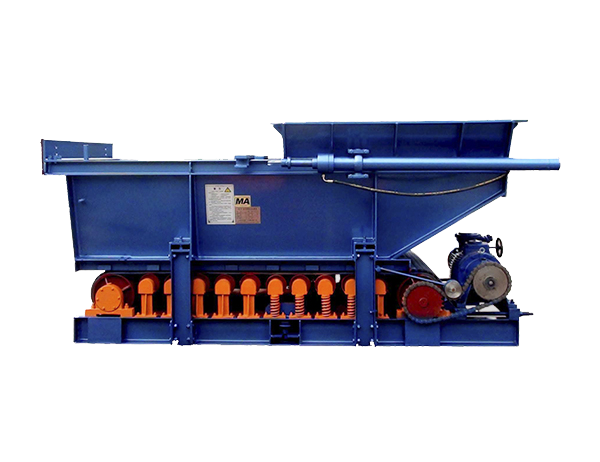

Four common faults of coal feeder and their solutions

Fault 1: feeder does not discharge

Treatment: check the running direction of the two motors and whether the soft connection is broken.

Fault 2: uneven cutting

Treatment: check whether there is coal deposit on the bottom plate.

Fault 3: motor overload

Treatment: check whether there is much coal around the bottom plate and dustpan, resulting in no gap between the dustpan and the discharge chute.

Fault 4: backward coal overflow

Treatment: due to the small slope of dustpan, large moisture content of coal or large feeding amount, adjust the slope and feeding ram.

Nine common faults of belt conveyor and their solutions

Fault 1: the reducer does not rotate

Phenomenon: the belt motor and hydraulic coupling are running, the reducer is not running, the hydraulic coupling fusible plug is normal, the oil level is normal, the backstop is free of temperature and peculiar smell.

Treatment: from easy to difficult troubleshooting, first check the reducer, then check and replace the backstop, and then check the hydraulic coupling.

Fault 2: the belt conveyor fails to start

Phenomenon: the motor does not run.

Treatment: check and remove the protection faults (stall alarm, dredge the chute, reset the pull rope switch, reset the emergency stop button), and check the motor.

Fault 3: belt deviation

Phenomenon: when the belt conveyor is in normal operation, the belt starts to deviate along a certain point.

Treatment: check whether there is slime or sundries on the roller and idler, check whether there is too much coal on the lower belt, and clean it.

Phenomenon: the whole conveyor belt runs to one side.

Treatment: drum is not parallel, mostly due to tail drum deflection or tail drum slime.

Phenomenon: the belt runs to one side, and the deviation is at the joint of the belt.

Treatment: if the joint is not correct, it shall be remade according to the standard.

Phenomenon: the direction of belt deviation is uncertain, left and right.

Treatment: insufficient tension, adjust the belt tension.

Phenomenon: the belt does not deviate under no load, and it deviates under load.

Treatment: adjust the coal dropping point or increase the supporting roller if the material falling is partial or the supporting roller under the loading point is damaged or missing.

Phenomenon: the middle part of the belt conveyor deviates.

Treatment: move the deviation idler according to the situation.

Fault 4: belt damage

Phenomenon: the belt stops running and is damaged

Treatment: the belt is seriously deviated, and the belt joint is torn on the frame or roller bearing seat; check whether the equipment parts fall off, the iron is stuck in the blanking chute and the belt room; whether there is large coal and gangue; whether there is chute liner fall off; the transmission roller stalls; the roller and the idler are damaged and scratched; the idler is stuck and inflexible; there is iron wire and other sundries stuck between the cleaner and the belt 。

Fault 5: tape slipping

Phenomenon: the resistance of the tape is too large.

Treatment: loading goods should not be too much and there should not be a large number of idlers that do not rotate.

Phenomenon: the tape tension is small.

Treatment: adjust the tension device, adjust the deformation and elongation of the new belt after a period of operation.

Phenomenon: the friction coefficient between the belt and the driving drum decreases.

Treatment: avoid the contact surface of the belt driving roller from entering mud water or washing water when cleaning.

Fault 6: Spray

Phenomenon: spray material at transfer point.

Treatment: spray materials in chute and guide chute, check whether the conveyor is seriously overloaded and whether the rubber apron of guide chute is damaged.

Phenomenon: sprinkling in case of deviation.

Treatment: adjust the deviation of the tape.

Phenomenon: when the conveyor is started, the concave section will spring up and sprinkle materials.

Treatment: the concave part of the conveyor is provided with a belt pulley to prevent the belt from springing up.

Fault 7: abnormal noise

Phenomenon: noise caused by serious eccentricity of idler.

Treatment: replace the idler.

Phenomenon: noise when two shafts of coupling are not concentric.

Treatment: adjust the position of motor and reducer.

Phenomenon: abnormal noise of steering drum and driving drum

Treatment: check the bearing at the bearing seat.

Fault 8: short belt life

Phenomenon: the service life of conveyor belt is short.

Treatment: check whether the tape has been stored for a long time and cracks. Check the tightness of the cleaner to ensure that there is no material on the return tape.

Fault 9: broken belt

Phenomenon: the belt breaks during operation.

Treatment: check whether the belt is overloaded, pull the empty belt when the machine is stopped, avoid heavy load starting, replace the idler without rotation in time, clean up the sundries and reduce the running resistance of the belt.

Phenomenon: fracture from joint.

Treatment: if the tensile strength of the belt joint is not enough, the belt joint shall be checked frequently and replaced regularly, and the damaged joint shall be replaced in time.

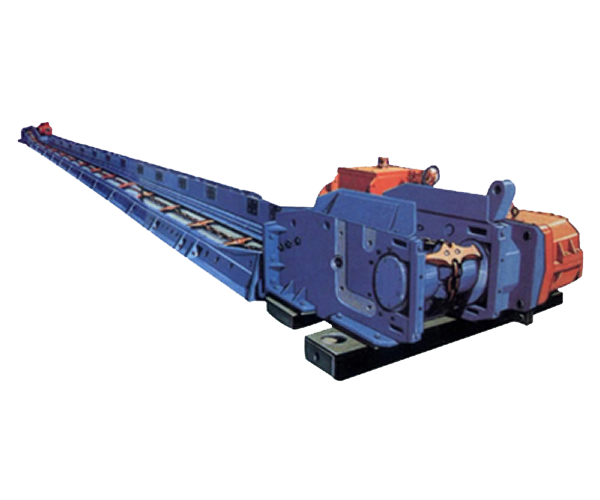

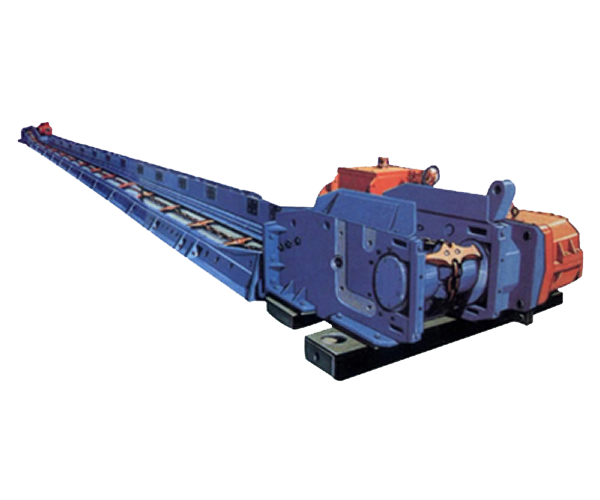

Five common faults of scraper and their solutions

Fault 1: chain jumping

Phenomenon: scraper chain jumps at sprocket

Treatment: the installation position of the connecting ring or the ring chain is readjusted due to incorrect installation of the connecting ring or "twist" of the ring chain; the sprocket teeth are excessively worn, and the new sprocket is replaced; the scraper chain is too loose, and it is re connected.

Fault 2: shutdown

Phenomenon: trip

Treatment: due to over-current and heavy load, check and take out stuck materials.

Fault 3: bent scraper

Phenomenon: the blanking is not correct, the hard object is stuck in the sprocket, and the scraper is bent

Solution: cut off the power, loosen the tail roller and take out the hard object, adjust the chain and replace the scraper.

Fault 4: broken chain

Phenomenon: Operation interruption chain

Treatment: due to impact and fatigue fracture, serious wear or corrosion, poor chain manufacturing quality, the corresponding measures are to reduce the dynamic load, replace the severely worn and corroded chain, and replace the unqualified chain.

Fault 5: floating chain

Phenomenon: chain goes up and down, left and right in operation

Treatment: the possible reason is that the groove bottom is uneven or small particles enter under the chain. The corresponding solution is to correct the groove bottom and add a cleaning plate.

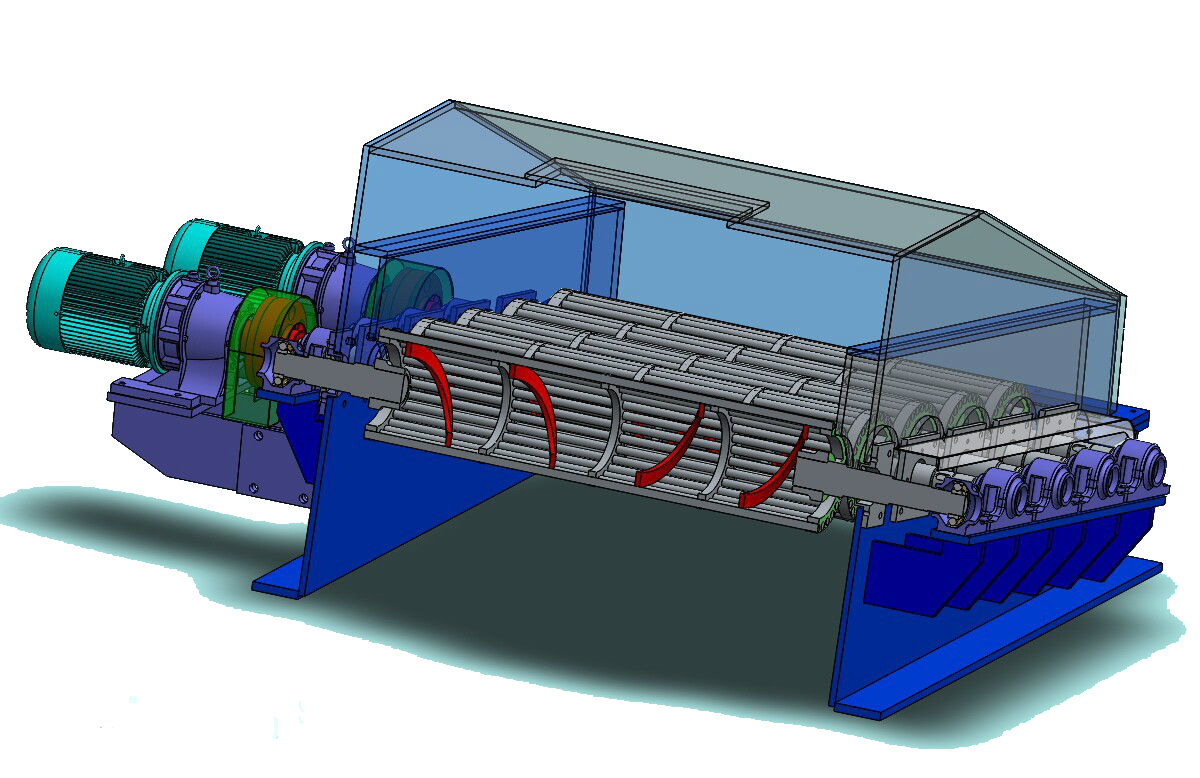

21 kinds of common faults of filter press and their solutions

Fault 1: insufficient pressure

Treatment: the overflow valve is damaged, repaired or replaced; the oil level is not enough, supplement the hydraulic oil; the oil pump is damaged, replace the oil pump ; the valve block and the joint are leaking, tighten or replace the O-ring; the oil cylinder sealing ring is worn, replace the sealing ring.

Fault 2: poor pressure maintaining

Treatment: the piston sealing ring is worn, replace the sealing ring; the oil way leaks, repair the oil way; the hydraulic control check valve is blocked or worn, clean or replace; the electromagnetic ball valve is blocked or worn, clean or replace.

Fault 3: broken filter plate

Treatment: If the feed pressure is too high during filtration, adjust the feed pressure; if the feed temperature is too high, change the high temperature plate or cool it before filtration; if the feed speed is too fast, reduce the feed speed; if the feed hole of the filter plate is blocked, clean the feed hole; if the filter cloth is damaged and the outlet is blocked, replace the filter cloth and clean it; if the coal cake is not full, clean and check to make the coal cake full.

Fault 4: filter plate up

Treatment: the installation foundation is not flat, and the foundation shall be reconditioned; the slag at the lower part of the filter plate is not clean, and it shall be cleaned.

Fault 5: the filtrate is not clear

Treatment: if the filter cloth is damaged, replace the filter cloth; if the filter cloth is not properly selected, retest and replace the filter cloth; if the opening of the filter cloth is too large, replace the filter cloth; if the suture of the filter cloth is opened, re suture.

Fault 6: noise in hydraulic system

Treatment: inhale air, open vent valve to vent; The fasteners are loose,tighten; excessive viscosity of hydraulic oil, reducing viscosity of hydraulic oil.

Fault 7: bent girder

Treatment: if the roughness of the foundation at the oil cylinder end is not enough, reinstall it; if the arrangement of the filter plates is not parallel and the pulling plates are not synchronous, rearrange the filter plates and adjust the synchronicity of the pulling plate trolley; if the head plates are not correct, the filter press support frame is deformed, and adjust it.

Fault 8: trolley does not pull the plate

Treatment: if the limit switch has no signal, adjust the position of the head plate; if the trolley is not in place, adjust the position of the trolley; if Y4 and Y5 do not act, replace Y4 and Y5 relays.

Fault 9: the filter cloth is damaged

Treatment: wash the filter cloth in time if there is much slime on it; replace the underflow nozzle if the primary cyclone runs rough.

Fault 10: Plywood timeout alarm

Treatment: if the closing proximity switch is broken, replace the proximity switch; if the pulling motor and frequency converter or reducer and chain drive mechanism are in fault, check and repair.

Fault 11: pressing timeout alarm

Treatment: the electric contact pressure gauge is damaged, check and replace; the hydraulic system is in fault, check and repair.

Fault 12: feed valve timeout alarm

Treatment: if the solenoid valve does not act, check and replace it; if the travel switch is broken, check and repair it; if the air pressure is not enough, check and repair it.

Fault 13: feeding pump fails to load normally after starting

Treatment: the coupling of motor and pump is damaged, check and repair; the feed pipe is blocked, clean.

Fault 14: shotcreting

Treatment method: the pressing force is not enough, increase the pressing force; the edge of the filter plate is mixed with slime, clean the slime; the filter cloth is folded, and the filter cloth is leveled.

Fault 15: stop pin does not move up and down

Treatment: if the proximity switch is in poor contact, check and replace the proximity switch; if the retaining pin mechanism fails, check the brake motor.

Fault 16: intake valve cannot be opened during pressing

Treatment: check the air compressor for low air inlet pressure; replace the air inlet pressure gauge if it is broken.

Fault 17: the filtrate pipe of the pressing time-space plate runs out of air

Treatment: if the filter plate is damaged, check and replace the filter plate; if the sealing ring of the air inlet of the filter plate is off, make up the sealing ring.

Fault 18: unloading release, panel shows release timeout

Treatment: The release proximity switch is broken, replace it; Hydraulic failure, check and repair.

Fault 19: head plate displacement too slow

Treatment: the oil on the high-pressure and low-pressure oil pumps is not normal, repair the oil filter, discharge the air in the pump, and check the performance of the high-pressure and low-pressure oil pumps.

Fault 20: the plate pulling device frequently impacts the handle of the filter plate, but does not return

Treatment: the oil for pulling plate is insufficient, the pressure relay does not act, adjust the flow of pressure relay spring and speed regulating valve, and increase the oil circuit pressure.

Fault 21: the oil pump is hot and does not supply oil

Treatment: if the motor or oil pump is not turned correctly, the oil is dirty, the oil level is low, the oil pump has problems, etc., adjust the rotation direction of the oil pump or motor; clean the oil pump and oil filter; refuel, check the oil pump, etc.

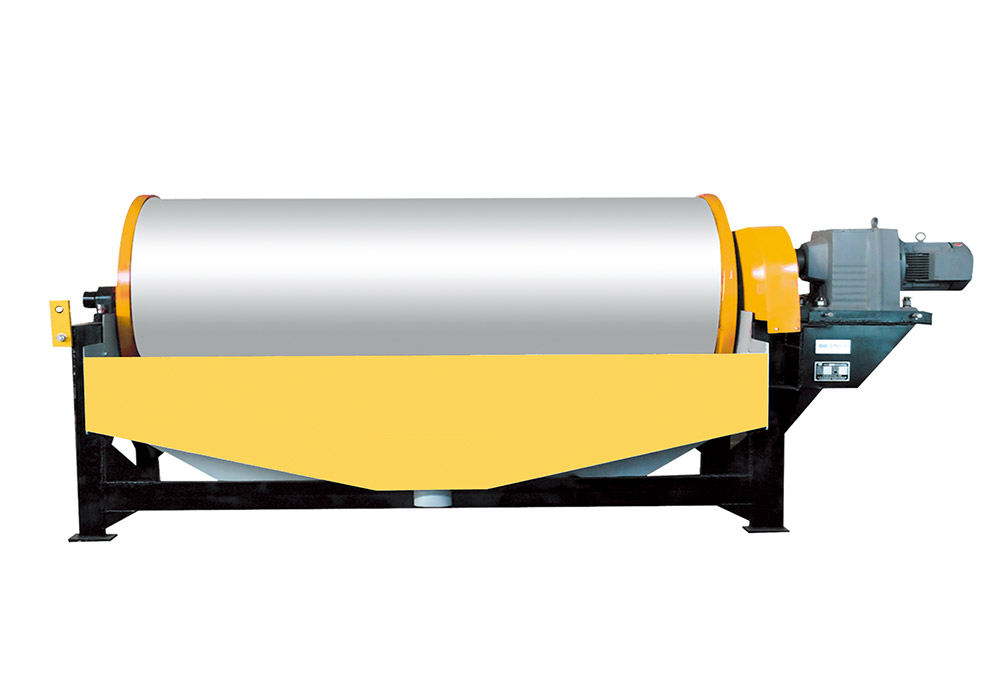

Nine common faults of magnetic separator and their solutions

Fault 1: magnetic separation efficiency decreases

Treatment: check whether the water level is low, reduce the discharge diameter of the tail until a certain amount of overflow overflows the downflow weir; The position of the magnet may be incorrect. If the concentrate is thick, rotate the magnet toward the discharge end.

If the concentrate is thin, rotate the magnet toward the feeding end; if the running gap is too large, readjust the roller position to reach the correct gap size; if the feeding coal slime is mixed with soil, use flocculant to remove the soil in the thickener;

If the screen gap of the demineralization screen becomes large or there is damage, the large particles entering the separation tank will increase and not be cleaned in time, resulting in no overflow or less overflow, which will shorten the magnetic separation area. The screen plate shall be replaced, and the materials in the separation tank must be flushed before starting each shift; the feed slime is mixed with flocculant, and the flocculant shall be removed from the thickener by using dispersant;

Fault 2: too much overflow

Treatment method: if the discharge diameter is too small, increase the discharge at the tail of the machine until a certain amount of overflow overflows the downflow weir; if the solid content of the feed is too high, increase the operation gap and recheck the overflow; if the roller position is too close to the feed end, reposition the roller; if the flow is surging, install the flow surging controller or improve the feed state before the magnetic separator is fed; if the bottom of the roller is blocked, install the flow surging controller at the roller Place a rubber belt at the bottom to check (move from one side to the other). If any blockage is found, lift the roller to remove the blockage.

Fault 3: low specific gravity of concentrate

Treatment: if the magnet position is too high, replace the magnet position; if the water level is too high, readjust the size of tailing bushing; if the discharge gap is too wide, move the drum forward.